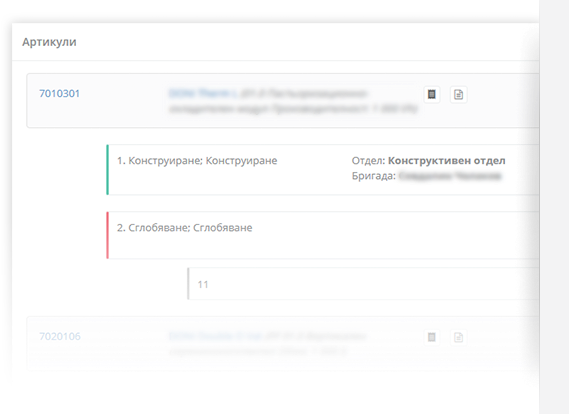

Production orders

Production orders can be generated from existing client orders or from internal request for lack of sufficient stock availability.

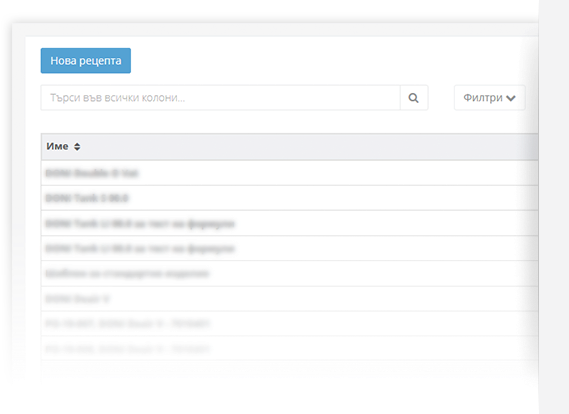

Recipes

Recipes module holds full description of the production process, the dependence between the related subordinate processes and the resources required for the production of each product. Recipes are the basis for generating production tasks and material requests.

Production tasks

Production task is assigned for each item in the production order and it corresponds to a certain technological process predefined in the recipe.

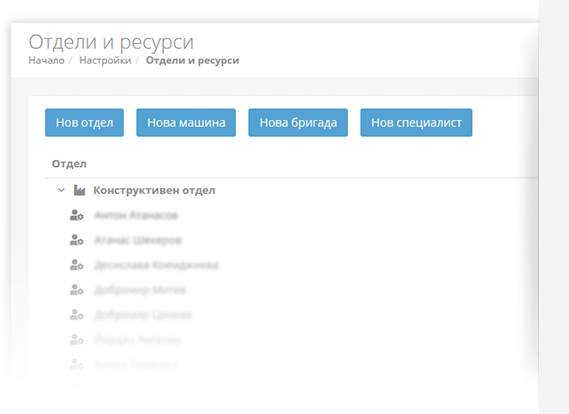

Departments and resources

Tasks are assigned to the departments (production or administrative) and their resources. Depending on the department and the specifics of the production resources can vary between teams, specialists or machines.

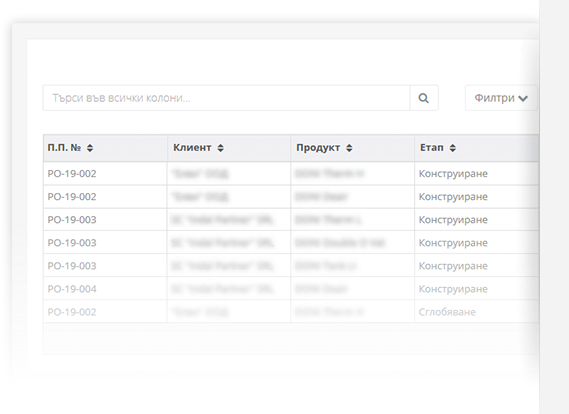

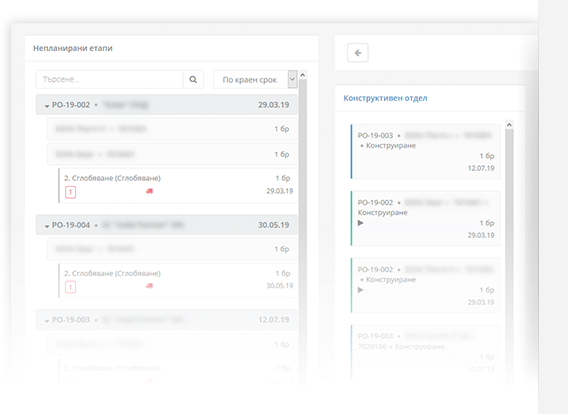

Planning

Workflow planning represents the assignment of production tasks to departments and resources. All tasks that can be handled by only one specialist or machine are assigned automatically. Visually the workflow schedule shows general information for each task - overdue deadlines, unfulfilled tasks blocking current ones, materials availability. This view enables managers to quickly analyze the situation and define problems and easily prioritize tasks.

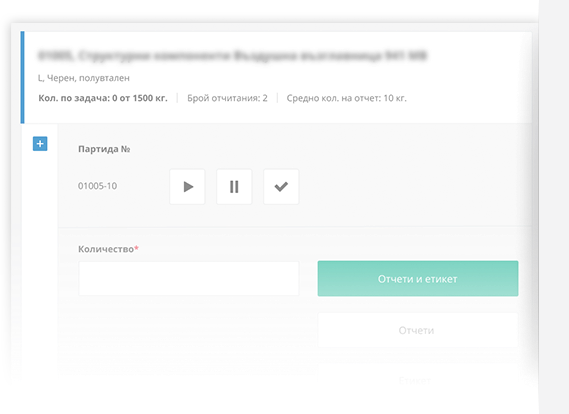

Reporting finished goods

Operators have access to their tasks ordered by priority. They can select the task they are executing and report when the products are finished.

This module is developed to operate on industrial PCs and can be connected to electronical scales and printers.

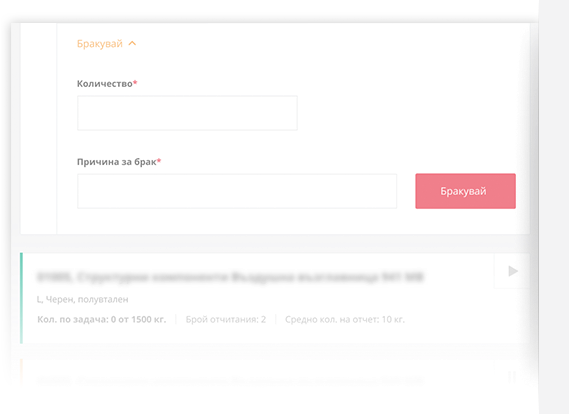

Waste management

The system supports different reasons for waste depending on the production specifics. Upon reporting the ready products wasted quantities can be also be imported in a separate batch. This procedure enables the tracking and further processing of the wasted quantities.

Materials input

Materials are automatically written-off with the reporting of ready products. Depending on the system settings materials are calculated based on the predefined recipe or on the actual usage during production.

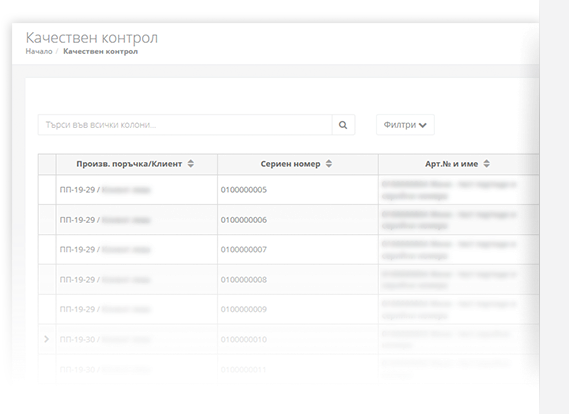

Quality control

Quality control can start from the initial stages of production and continue even after the reporting of ready products. Each company can provide a standard test check-list for quality control which needs to be followed. The operators can follow the results from those tests and take prompt actions in case of a problem.

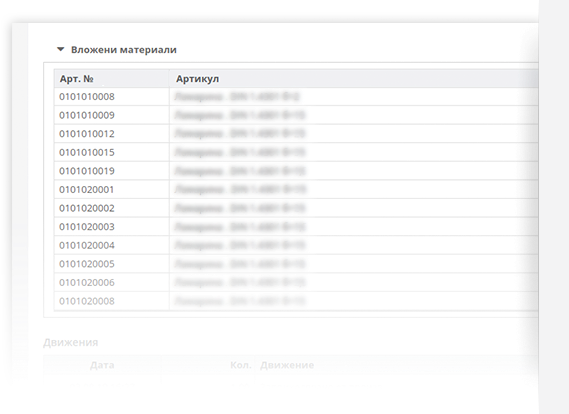

Product passport

The system generates a passport for each batch or serial number which holds detailed information about: who and when produced the goods, materials used, the production costs, which is the client order, etc.